The following systems incorporate customized hardware, sensors and software for integrated ultrasonic weld inspection applications (in-line or off-line). The list below covers the most common applications.

TAILOR WELDED BLANKS (EMAT)

Industry standard for volumetric inspection of tailor welded blanks. Detects surface and internal defects at production speeds.

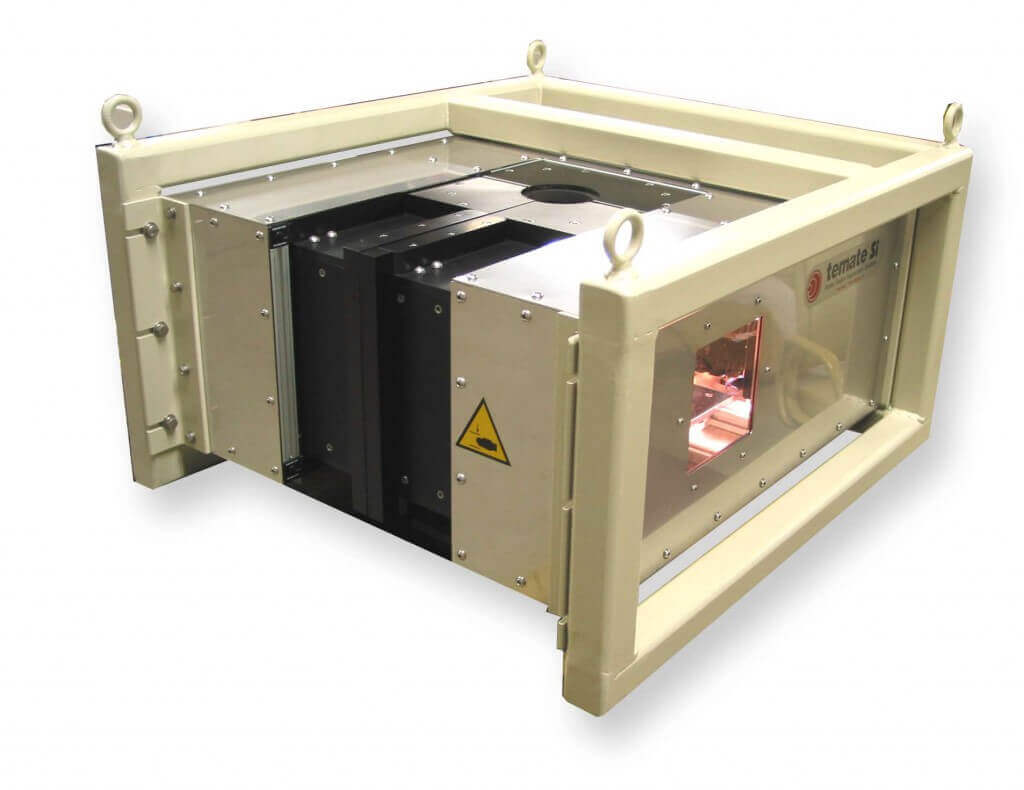

COIL WELDS IN MILL FINISHING LINES (EMAT)

The TEMATE SI-MWC and TEMATE SI-LC are designed for automated inspection of Mash Welds and Laser Welds.

THIN WELDS (<6mm) (EMAT)

TEMATE SI-BW is designed for inspection of thin butt welds less than 12mm.

FLASH-BUTT WELDS IN PICKLE LINES (EMAT)

Weld inspection in pickle lines without additional cycle time. Detects defects caused by misalignment, poor trimming, and welder failures.

IN-LINE ERW TUBE WELDS (EMAT)

Weld inspection for longitudinal ERW pipe immediately after welding.

ERW AND SAW TUBE AND PIPE WELDS (PAUT)

Ultrasonic Phased Array inspection of linear welds on SAW and ERW pipes and tubes.

MULTI-PASS WELDS, INSPECTION WHILE WELDING IWW (EMAT)

Ultrasonic inspection of multi-pass welds after each welding pass at temperature up to 200⁰C.